This is the only part left borrowed. I have no idea what this was originally from, or where to get one. If you readers have any clue, feel free to comment. This is the spur gear hub. Since the wheels/tires we’re going to install no longer work with the bolt on pan car wheel/spur hub, we need a separate hub for the spur.

For gearing, we are changing the ratio and getting is as low as legally possible for this class. The stock spur gear is a 54 tooth 32 pitch gear. We will be gearing down to a 64 tooth spur from the RC10GT (7662).

Here you can see how much bigger this spur is compared to stock.

The next change we will make is the pinion gear. The stock pinion is 11 tooth. What we borrowed for the Hanger Pull was an 8 tooth. The smallest pinion allowed is a 6 tooth! 6!! It was tough to find, but I managed to find one at RC4WD. The lowest tooth that Robinson Racing makes is a 9 tooth, so this is a specialty item for sure. Below is our new 6 Tooth pinion.

Below is the 6 tooth compared to a 9 tooth available from Robinson.

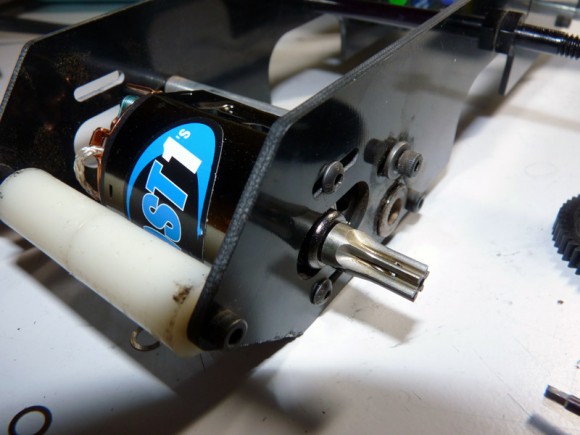

Here’s the beast installed.

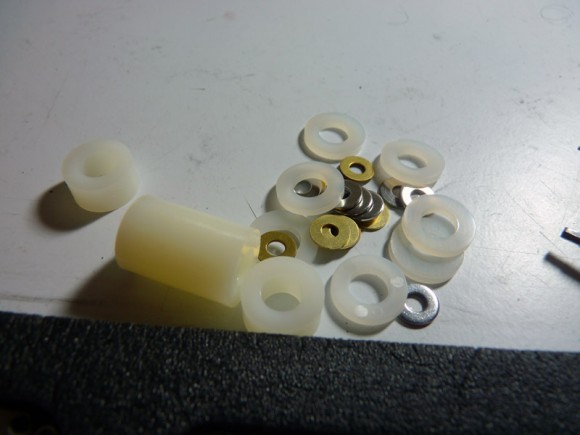

All these gear/hub changes will require changes in shimming of the axle. I picked these up at my local hardware store. It is a variety of 1/4″ (rear axle) and 1/8″ (front axle) shims, washers, and spacers. I HIGHLY suggest getting these for proper spacing.

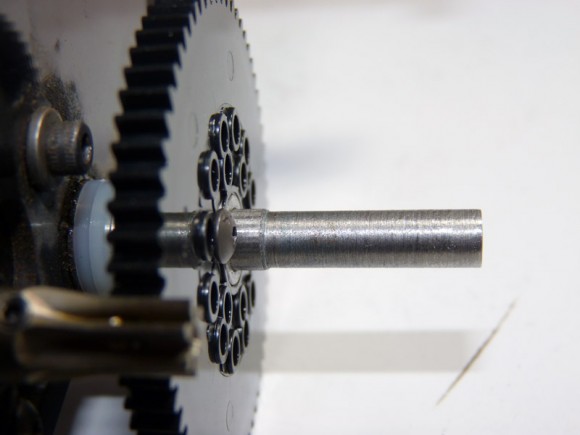

Here you can see the axle shimmed out for proper spur alignment with the pinion.

As with the original build up, I decided to use another coating of PPR-Slots Z-Opt RC Lite Grease to lube the factory axle bushings.

This is the left hand side of the axle. Because this side does not have the spur hub, it needs a lot more shims to space it correctly.

I want to point out, if you haven’t already noticed.. that the hubs I ended up using for this didn’t quite fit the axle. Our friends at AJS Machine once again saved the day by helping us turn down the axle on their lathe. It wasn’t off by a lot. I believe it was .012″ tolerance that we ended up removing for the hubs to fit, maybe a little more. Anyone who needs custom machining done can hit up AJS Machine, they are R/C Friendly.

April 11th, 2012

April 11th, 2012  Kevin

Kevin

Posted in

Posted in  Tags:

Tags:

Very nice Kevin. Puller looks awesome. Good luck this weekend!

So where are you guys attaching the sled to the diggers? I pull and think this would be an awesome cheap class to start. I have prob 4 of these chassis already. Thanks

We just use the wheelie bar. I still need to cut out the spot in the body for access though.

The spur gear hub you can get from outlawhobbies.com and I believe servocity.com

Are there other wheels and tires there using like a tlt wheel and tire? Sorry for all the questions but I think this would be a good class to add to ours . Just doing some homework before I suggest us adding this class.

[…] this event in 2wd Box Stock class. We also officially revamped our RJ Speed Digger into “Project Puller“. We ran the Digger last event too, using borrowed parts and Kris Button (Official RC Soup […]